Confined Flow Underdrains for Water Treatment Plants

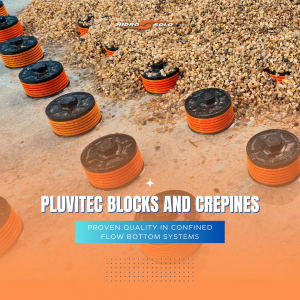

15 de fevereiro de 2024Pluvitec® Blocks and Crepines are part of the confined fund underdrain system develo [...]

22 nov 2022

By: Hidrol Team

Posted on: Water treatment

The adoption of sustainable practices by industry has taken on great importance in business discussions in recent years. Hidro Solo celebrates its 40 years evolving in this regard. Improving production, ensuring energy efficiency through renewable energy sources and reducing the use of pollutants is the company's focus to expand growth with quality and environmental responsibility.

In recent years, aiming to converge with global and climate pacts and reaffirm its commitment to the environment, Hidro Solo has adopted three main practices to ensure a cleaner production. Check out:

Photovoltaic Power Plant

In the first half of 2022, the installation of a photovoltaic power plant at our factory has started. With the conclusion and start-up of the clean energy plant, Hidro Solo is generating more than 13,000 kW/h per month. There are more than 200 solar panels that will ensure the end of the consumption of electricity from conventional production from other sources.

According to the Brazilian Association of Photovoltaic Solar Energy (Absolar), Brazil has reached a capacity of 19 gigawatts (GW) installed in solar projects, adding up to self-generation systems for electricity on roofs, facades and small plots of land. This mark already corresponds to 9.6% of the country's electricity matrix.

From January to the beginning of September 2022, the solar capacity installed grew up by 46.1%, from 13 GW to 19 GW. The pace of expansion, according to Absolar, has been 1 GW per month.

Use of natural gas

Natural gas is present on several fronts of Hidro Solo's production processes. As it is a metallurgical industry, we use natural gas in the boiler, since it offers, in addition to good burning efficiency and thermal performance, a cleaner burn than other gases. Beyond the boiler, natural gas is used in the aluminum foundry and in the electrostatic painting oven, ensuring high quality production.

Effluent drying by sunlight

Another important sustainable practice is the use of sunlight to dry effluents. During production, after the acid pickling process, the materials are washed to remove the acid, and only then are they dipped in a phosphatizing agent. Both this acid washing water and the phosphatizing agent cannot be improperly discarded. This way, both solutions have their pH's corrected and are sent to the drying process by sunlight in an oven installed at the factory.

Are practices like these that make the industry move forward with environmental responsibility. This commitment is collective and allows us to envision a better future. Hidro Solo will continue to expand these practices, adopting new means of protecting the environment, in order to become a more sustainable company each year, and investing in technology and innovations.

Pluvitec® Blocks and Crepines are part of the confined fund underdrain system develo [...]

In its 43-year history Hidro Solo maintains its focus on innovating and growing, pro [...]

Pluvitec Blocks and Crepinas, products with the Hidro Solo identity and technology f [...]